Thermal Ceramics

Refractory Fired Shapes

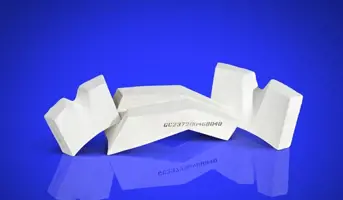

High alumina, silicon carbide, nitride bonded silicon carbide and fused silica formulations, for the most demanding metals applications.

We engineer market leading refractory crucibles, distribution boxes, hot top boxes, tubes, nozzles and shapes for a variety of critical duties in vacuum induction melting and other heat intensive applications greater than 1649°C (3000°F), under our Cerox®, Morsil® and Valcor® brands.

Our fired refractory crucibles, distribution boxes, hot top boxes, tubes, nozzles and shapes are made using high alumina, silicon carbide, nitride bonded silicon carbide and fused silica formulations. These materials allow us to engineer the optimum solution for reliability and durability, even under the most arduous conditions.

Our thixotropic casting manufacturing process allows for crucibles and shapes to be made to precise customer specifications. Thixotropic casting uses a dispersion agent, which allows the mix to flow when vibrated without requiring high water content. These manufacturing techniques, combined with precisely controlled firing and 100% product inspection, produce high-quality components suited to the most arduous of high temperature environments. Our crucibles are available in a range of sizes from 136 kg up to 2.7 mt (300 lb – 2000 lbs).

Refractory Fired Shape Product Data Sheets

Benefits of our fired refractories solutions are:

- High thermal conductivity and refractoriness, low thermal expansion and outstanding abrasion/erosion resistance, thanks to alpha silicon carbide crystals

- Wide choice of bonding options ensures properties can be matched to application needs; such high operating temperatures, resistance to corrosion or thermal shock, strength

- Low gas permeability

- Tight tolerance capability

Our Cerox, Valcor and Morsil products are typically used in these melting applications:

- Crucibles, tundishes and launder systems

- Furnace spouts, distribution boxes, hot tops and metamics - metal-ceramic composite thermocouple sheaths

- Muffles, ladle liners, saggars, sealed quench furnace muffle assemblies

- Kiln furniture

- Consumable glass-contact refractories

Explore more Product and System resources

-

Brochures and Flyers

-

Thermal Ceramics Product and System Solutions

Download (pdf 2.89mb) -

Thermal Ceramics At a Glance

Download (pdf 278.78kb) -

Superwool Plus and Superwool Prime Low Biopersistent Fibres Portfolio

Download (pdf 2.83mb)

-

-

Installation Manuals

-

Pyro-Bloc M Module Design and Installation Manual

Download (pdf 1.59mb)

-

-

Case Studies

-

Case Study: WDS Microporous in back-up insulation for Iron and Steel ladle

Download (pdf 742.94kb) -

Case Study: Mont Blanc Tunnel

Download (pdf 170.73kb) -

Case Study: Faver Tunnel

Download (pdf 180.19kb)

-